A wind tunnel is a machine that simulates the flow of air over objects. It usually consists of a long, narrow tube where airflow is introduced via different methods, such as powerful fans.

Models or objects are placed inside the tube, and airflow is controlled to study its effects on such objects under different conditions, such as varying wind speeds.

First developed in the late 19th century, wind tunnels are now widely used across various industries. For instance, wind tunnels are used in the automotive industry to test the aerodynamics of cars, racing cars, trucks, and other vehicles.

Stay ahead of your peers in technology and engineering - The Blueprint

In civil engineering, these tunnels help test the structural integrity of buildings and infrastructure projects.

They have also become a mainstay in the aerospace industry, helping to test the aerodynamics of aircraft and rockets and optimizing their design for safer and more efficient flight.

Here are the top 7 most powerful wind tunnels today.

1. JF-22

The JF-22 is known as the world’s most powerful hypersonic wind tunnel. Built at the Institute of Mechanics of the Chinese Academy of Sciences (IMCAS) in northern Beijing, the JF-22 can reach speeds as high as Mach 30 or 6.4 miles per second (10.3 kilometers per second).

This is 30 times the speed of sound and six times the starting limit of hypersonic speed at Mach 5.

The JF-22 doesn’t use fans since these aren’t able to produce such high-speed airflows. Instead, it uses timed explosions to generate shock waves that reflect off each other and converge at a single point within a tube of 13 feet (4 meters) in diameter and 550 feet (167 meters) in length.

The JF-22 can provide up to 15 gigawatts of power. This is almost 70 percent of the capacity of the Three Gorges Dam— the largest hydropower station in the world, located in Yichang, China.

2. JF-12

The JF-12, often considered to be a predecessor to the JF-22, is an open-circuit wind tunnel.

Just like China’s most recent JF-22, the JF-12 uses shock waves to generate flight conditions from Mach 5 to Mach 9 at an altitude from 82,000 feet (25,000 meters) to 164,000 feet (50,000 meters).

Built by the Institute of Mechanics in the Chinese Academy of Sciences between 2008 and 2012, the JF-12 is believed to have been vital in the development of China’s DF-ZF hypersonic glide vehicle (HGV), according to a Hypersonic Systems Development report from the China Aerospace Studies Institute.

The JF-12 is still operational, and, reportedly works alongside the JF-22.

3. T-117 TsAGI Hypersonic Wind Tunnel

The T-117 TsAGI is a large hypersonic blowdown arc heater wind tunnel built at the Central Aerohydrodynamic Institute, Moscow, Russia, in the 1970s.

It operates on a blowdown principle, where high-pressure gas is rapidly released into the test section to create airflow.

Two separate electric arc heaters— which can be swapped out depending on the experiment— heat the airflow.

One heater uses two electric arcs to provide a maximum power of 25 megawatts, while the other uses one electric arc to deliver a maximum power of 2.5 megawatts.

The air in these arc heaters is heated between two electrodes aligned along the same axis, generating an electric arc. The electric arc is rotated using a magnetic field, heating the air passing between the electrodes as it moves and rotates.

This way, the T-117 TsAGI can replicate the high temperatures that hypersonic vehicles can encounter during flight, while also generating testing speeds from Mach 5 to Mach 10.

In 2018, the T-117 TsAGI was used to test the hypersonic flight modes of the Federation return spacecraft, a Roscosmos project intended to supplant the Soyuz spacecraft for different operations on the low Earth orbit and the Moon.

4. Hypersonic Tunnel Facility (HTF)

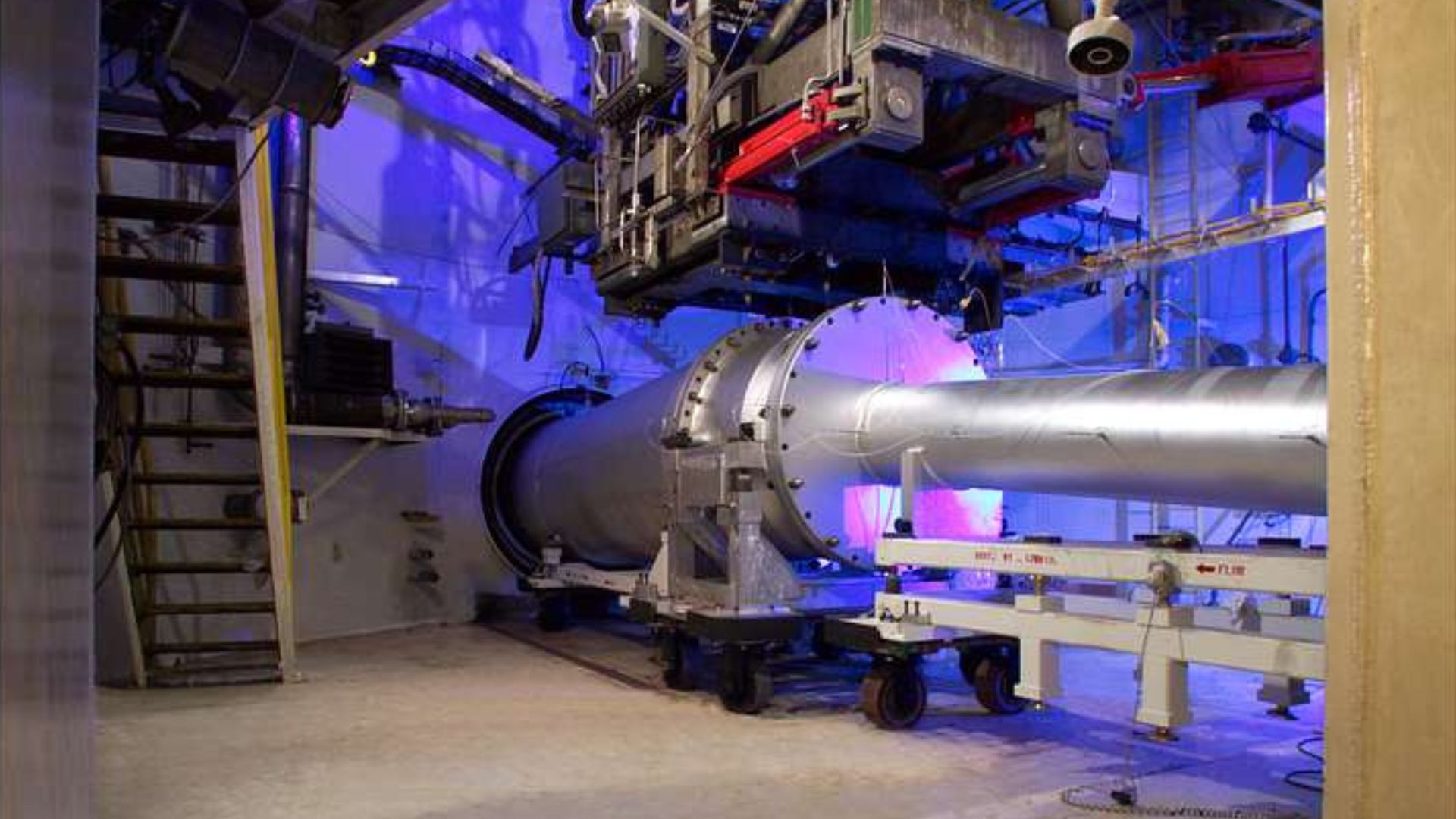

The Hypersonic Tunnel Facility (HTF) is located at NASA’s Neil Armstrong Test Facility, a remote campus of Glenn Research Center in Sandusky, Ohio.

Originally built to test nuclear thermal rocket nozzles within the Nuclear Engine for Rocket Vehicle Application (NERVA) program, it now serves to test large-scale, hypersonic air-breathing propulsion systems at speeds ranging from Mach 5 to Mach 7 with true altitude simulation (up to 120,000 feet or 36,500 meters).

The HTF’s test section is adjustable from 10 feet (3.05 meters) to 14 feet (4.27 meters). There, a graphite core storage heater heats nitrogen gas, which is then mixed with ambient-temperature oxygen and ambient-temperature nitrogen to create true-composition, uncontaminated synthetic air.

The temperature of this synthetic air is manipulated to match the specific temperature required for the testing.

The HTF can be active for up to 5 minutes at a time, depending on operating conditions.

5. Unitary Plan Wind Tunnel (UPWT)

The Unitary Plan Wind Tunnel (UPWT) is one of the largest operational wind tunnels in the world. It is located at the NASA Ames Research Center in Moffet Field, California.

Since its completion in 1955, the Unitary Plan Wind Tunnel (UPWT) has been used to test both traditional aircraft (commercial and military) and spacecraft (such as the NASA-built, now-retired Space Shuttle).

It has played a key role in the development of the Boeing fleet, as well as the F-111 fighter and the B-1 Lancer bomber.

The UPWT contains three closed-loop wind tunnels: the 11-by-11-foot Transonic Wind Tunnel (TWT), the 9-by-7-foot Supersonic Wind Tunnel, and the 8-by-7-foot Supersonic Wind Tunnel.

The latter is capable of reaching speeds as high as 3.5 Mach. All sections are powered by four 65,000-horsepower wound-rotor-type induction electric motors working at 7200 volts.

The UPTW was recognized as a National Historic Landmark in 1985.

6. National Full-Scale Aerodynamics Complex (NFAC)

Operated by the U.S. Air Force’s Arnold Engineering Development Complex, the National Full-Scale Aerodynamics Complex (NFAC) is another wind tunnel facility located at NASA Ames Research Center in Moffett Field, California.

The facility earned its name from the ability to test full-scale and large-scale air vehicles, from commercial planes like the Boeing 737 to the parachutes of the Curiosity rover that landed on Mars in 2012.

The NFAC comprises two test sections, 40 by 80 feet and 80 by 120 feet. While the first one was built in 1944, a second section was added later in 1987, along with six fans measuring 40 feet in diameter each.

These fans use their 22,500-horsepower electric motors to extract air from the outdoors and pass it through the 80-by-120-foot test section at a maximum speed of 115 mph (185 kmh), reaching 345 mph (555 kmh) in the 40-by-80 foot test section.

The NFAC is equipped with a Data Acquisition System (DAS) that captures data during testing through advanced methods.

For example, it has one processor that processes incoming data streams from sensors and instruments in real time and another post-point processor that takes all the acquired data and provides valuable insights, facilitating in-depth analysis of the test results.

7. National Transonic Facility (NTF)

The National Transonic Facility is the world’s largest pressurized cryogenic wind tunnel. Located at the Langley Research Center in Hampton, Virginia, the NTF utilizes high-pressure nitrogen gas to reach temperatures up to -250°F (-156°C).

While it can work at ambient temperatures like conventional wind tunnels, the NTF’s ability to recreate cryogenic conditions helps it increase its Reynolds number capability to the point that it currently provides the world’s highest Reynolds number testing capability.

The Reynolds number is a dimensionless quantity used in fluid dynamics to characterize the flow of fluids, including air, around objects.

It represents the ratio of inertial forces to viscous forces within the fluid flow. As the Reynolds number increases, flows pass from laminar to turbulent.

Predicting this transition can help adapt aircraft design for better performance, efficiency, and stability, hence the importance of the National Transonic Facility for Reynolds number testing.

While the NTF is not a full-scale wind tunnel, it has been used to test small-scale (1/50) models of the Boeing 777 and 787, the B-2 bomber, the A-6 Intruder, and the F-18 Hornet.

57

57